-

+91 7383115721

Aluminum Strip foil is an outstanding barrier to humidity, mist and gases. It completely blocks the passage of light and entry of unwanted odours. Each Tablet is separately guarded.

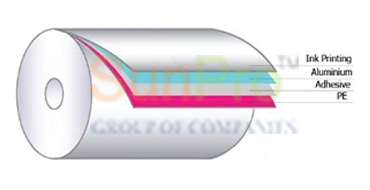

Laminated foils can be offered both un-printed and printed strip foil as per customers requirements in Foil/LDPE and Foil/HSL formations.

These are extraordinary foils with common lamination of LDPE of 150 gauge or 35-37 micron on the aluminum foils. Employed for aluminum tablet packing as strips both side with printing

Soft fully annealed aluminium alloy AA 8011 / AA 1200 conforming to Aluminium Association specification.

| Std Foil Gauge Options | Tolerance ( +/-8% ) | Min. Bursting Strength |

| 0.025 mm | +/- 0.002 mm | 1.5 kg/sq. cm |

| 0.030 mm | +/- 0.0024 mm | 1.9 kg/sq. cm |

| 0.040 mm | +/- 0.0032 mm | 2.5 kg/sq. cm |

Colourless LDPE conforming to the applicable Government regulations regarding direct contact with medicines and drugs

| Standard Polymer Gauge | Nominal | Tolerances ( +/- 15% ) |

| Options | GSM | GSM |

| 150 | 34.39 | +/- 5.16 |

| 180 | 41.27 | +/- 6.19 |

| 200 | 45.85 | +/- 6.88 |

| IDENTIFICATION: | Each reel shall be identified with a sticker with Reel number, Specification, Net weight, Gross weight, Operator name & Date manufacture. |

||||||

| PACKING: | Pharma foils are packed in cardboard carton. Relevant makings are provided on each outer Package. | ||||||

| RECOMMENDED OPERATING CONDITIONS: |

Sealing temperature Sealing pressure Dwell time |

: 130 to 150 deg. C : 2.8 to 5.6 kg/sq. cm or 40 to 80 lbs/sq. inch : 0.25 to 0.5 sec. |

|||||

| COVERING AREA OF 1 Kg FINISHED MATERIAL ( NOMINAL ) | Gauge & Temper Foil | Covering area in sq. mts/kg with 150 Gauge Polyethylene lamination | |||||

| 0.025 ( soft ) 0.03 ( soft ) 0.04 ( soft ) |

9.78 8.64 7.00 |

||||||

| TABLE SHOWING THICKNESS TOLERANCES OF FOIL: | Foil Gauge | Thickness ( mm ) | GSM | ||||

| Min. (-8%) | Nominal | Max. (+8%) | Min. (-8%) | Nominal | Max. (+8%) | ||

| 0.025 mm | 0.023 | 0.025 | 0.027 | 62.33 | 67.75 | 73.17 | |

| 0.03 mm | 0.028 | 0.030 | 0.032 | 74.80 | 81.30 | 87.80 | |

| 0.04 mm | 0.037 | 0.040 | 0.043 | 99.73 | 108.4 | 117.07 | |

| THICKNESS TOLERANCE OF POLYETHYLENE: | Poly Gauge | Thickness ( mm ) | GSM | ||||

| Min. (-15%) | Nominal | Max. (+15%) | Min. (-15%) | Nominal | Max. (+15%) | ||

| 150 | 0.0319 | 0.0375 | 0.0431 | 29.23 | 34.39 | 39.55 | |

| 180 | 0.0383 | 0.045 | 0.0518 | 35.08 | 41.27 | 47.46 | |

| 200 | 0.0425 | 0.05 | 0.0575 | 38.97 | 45.85 | 52.73 | |

| TEST CERTIFICATES: | Test certificates giving the actual observed values of different parameters will accompany the supplies. | ||||||