-

+91 7383115721

A flexible packaging structure typically consists of multiple layers of materials laminated together, with each layer performing a crucial role in your packaging’s performance and presentation.

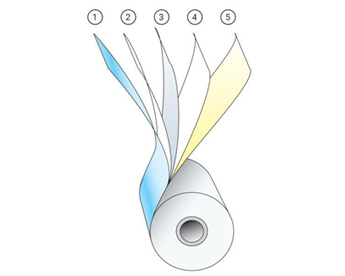

Each layer provides specific performance characteristics, such as:

The example below shows the duties each layer performs within a basic five-layer extrusion laminated flexible packaging structure

1. Exterior Layer

2. Tie Layer

3. Barrier layer

4. Tie Layer

5. Sealant Layer

Based on your requirements (including regulatory, cost, and aesthetic requirements), packaging equipment, product formulation, projected life cycle, and distribution methods, we can custom-engineer and suggest optimal flexible packaging structures for each of your products.

Flexible packaging offers a wide range of customization. You’re able to select and optimize your product packaging in practically any shape or size to ensure you are meeting the needs and wants of your target market, and speaking their language.

The ability to print with high-quality graphics on most flexible materials allows you to reduce costs in labeling while adding the eye-catching impact your product needs to stand out among the competition in the retail space. This allows you to be more competitive in the retail space as well.

Unique and creative packaging is going to stand out on the shelf. This brings opportunity to drive more interest and sales your way.