-

+91 7383115721

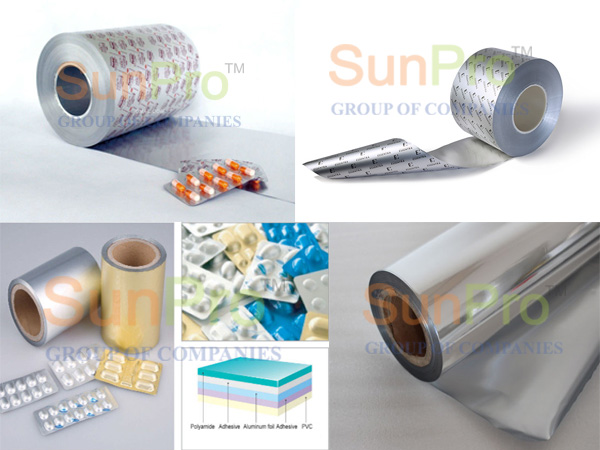

Cold Forming Blister Foil is tremendous multifaceted arrangement planned for high responsive series of Pharmaceutical and generic medicines which are extremely hygroscopic or light responsive and cannot be rightfully packed with barrier plastic films. The composition is an optimized amalgamation of aluminium foil and polymeric films with the alumina sheet packed in amid an interior heat sealable polymeric film and external kind malleable film.

| Structure details | Finish GSM (+/-8%) | Finish Mic (+/-8%) | |

| Structure | 25 micron OPA Film /Adhesive/45 micron Aluminium foil/ Adhesive/60 micron PVC film |

229-259 GSM | 135-145 MICRON |

| Structure | 25 micron OPA Film /Adhesive/50 micron Aluminium foil/ Adhesive/60 micron PVC film |

242-272 GSM | 140-150 MICRON |

| Structure | 25 micron OPA Film /Adhesive/55 micron Aluminium foil/ Adhesive/60 micron PVC film |

255-285 GSM | 145-155 MICRON |

| Structure | 25 micron OPA Film /Adhesive/60 micron Aluminium foil/ Adhesive/60 micron PVC film |

268-298 GSM | 150-160 MICRON |