-

+91 7383115721

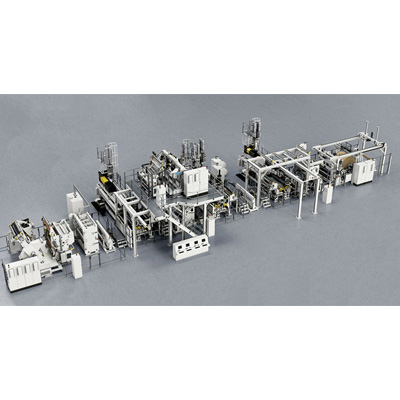

The highly advanced state-of-the-art infrastructure at SunPro® Group has been parted into several highly operational units, for reasons of managing the firm’s operations in the best possible manner. To help us in the attainment of a number of the firm’s predefined targets, the facility has been equipped with all the necessary machinery and equipment. Further, regular up-gradation of the facility, has helped us in maximizing our reach in the market.

The 100000 sq. ft. yards of facilities at SunPro® Group are state-of-the-art, strategically located and are fully configured for integration. This allows us to satisfy all manner of client requirement with respect to the type of lamination required, quality and also their quantity. We keep upgrading the machines and equipment used in our facilities to ensure a seamless production and dispatch process that meets the highest standards of efficiency. Our machine inventory includes a Hydraulic Press that has an installed capacity of 6o tons. We also check our machines regularly in order to maintain topnotch standards of maintenance so that they keep delivering optimum performance.