-

+91 7383115721

Made from heat-resistant laminated plastic, retort pouches are semi-rigid, flexible packages. Food products like soups, pasta, rice, sauces, and cook-in-a-bag meals are sealed and sterilized in these pouches with a maximum temperature of 121°C. Thus, they are the go-to packaging for convenience, processed, and pre-packaged food.

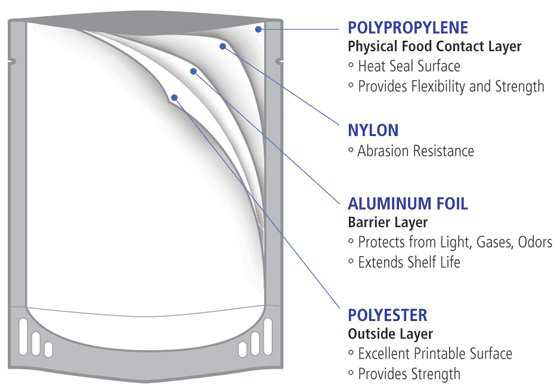

When we wax praises about how well retort pouches package, it is because of its internal structural composition. It has the sturdiness of metal cans and protects the nutrient value of the food.

The first layer is propylene which acts as a heat seal surface and provides strength and flexibility.

The next layer which is the nylon layer protects from abrasion.

The aluminum layer not only protects from lights, gases, and odor but also extends the product shelf life.

The final polyester layer provides excellent strength and is very easy to print on.

The materials that go into the packaging of retort pouches are FDA approved and undergo sterilization processes which increase the durability of the packaging.

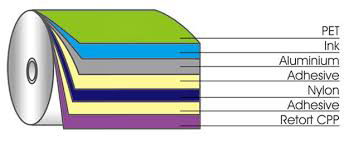

The structure of the high-temperature resistant cooking bag has two layers, three layers, four layers, and even more.

Among them, the second layer is a transparent plastic/mold, such as PET / CPP or OPA / CPP.

The three layers are transparent plastic/mold, such as PET / OPA / CPP, and opaque types containing aluminum foil, such as PET / AL / CPP, OPP / AL / CPP.

The four layers are opaque PET / AL / OPA / CPP with aluminum foil. This structure is a puncture-resistant, reinforced, large-capacity packaging bag. The OPA should be reasonable between AL and CPP.

The more layers are mainly The inner layer does not use pure CPP film, but uses multi-layer co-extruded film, such as PA / EVOH / PP, PA / PVA / PP co-extruded film plus PET or aluminum foil to form a composite with more layers, but its quantity Not much.

From a functional point of view, the four-layer structure PET / AL / OPA / CPP bag containing aluminum foil can completely meet the requirements of all cooked food.