-

+91 7383115721

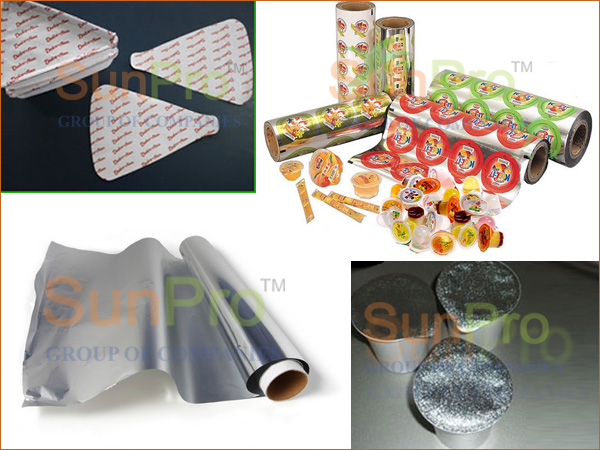

SunPro® Foilk-Pack produces variety of LIDDING FOIL appropriate for sealing to PS (Polystyrene), PVC (Polyvinyl Chloride), PP (Polypropylene) PET (Polyethyleneterphthalate) , PE (Polyethylene) and HDPE (High Density Polyethylene) jars/cups/tubs substrates with the following all-purpose specification.

Aluminium foil thickness: from 20 microns to 45 microns Coating: one side with primer suitable for printing and/or other side with thermosealing lacquer.Width, inner core diameter and outside diameter: according to customer's requirements.

Sealant & Coating : Contradictory type materials request for different sealant film or lacquer for compatibility. One side of the foil is either coated with a heat seal lacquer or laminated with apt polymer films. The types of sealant are

| Std Foil Gauge Options | Tolerance ( +/-8% ) |

| 0.03 mm | +/-0.0024 mm |

| 0.038 mm | +/-0.00304 mm |

| 0.04 mm | +/-0.0032 mm |

| Tub Material | Sealant Layer | Coating GSM/Film Thickness |

| PS | Lacquer | 6-8 +/- 1GSM |

| PVC | Lacquer | 6-8 +/- 1GSM |

| PP | Lacquer | 6.8 +/- 1GSM |

| PET | Lacquer | 6-8 +/- 1GSM |

| PE | Film | 125-150 +/- 15% Gauge |

| HDPE | Film | 125-150 +/- 15% Gauge |

| Configuration | Lidding foils are accessible in slit reel form or punched disc ( precut ) form. |

| Embossing | The punched discs are pinhead or Moroco embossed. |

| Core | Material Options : (a) Aluminium (b) MS (c) Card Board Core I.D. : Aluminium and MS ; 76 mm +/- 0.5 mm or 152 mm +/- 1mm Card Board : 76 mm +/- 0.5mm |

| Reel Size | Reels are delivered with an O.D. of 400 +/- 10 mm maximum or as specified by the customer. |

| Identification | Each reel is identified with a ticket having reel number, specification, operator number and manufacturing date. |

| Packing | Packed in cardboard carton. For export, the reels are packed in wooden crate/box. Relevant markings are provided on each outer package. |

| Test Certificates |

Test certificates giving the real observed morals of diverse parameters will convoy the supplies. |

Lidding Foil is appropriate for sealing to PVC (Polyvinyl Chloride), PP (Polypropylene), PET (Polyethyleneterphthalate), PE (Polyethylene), HDPE (High Density Polyethylene), PS (Polystyrene). Our Aluminium Lidding Foil is made in accordance with the mentioned specifications of the client. We make sure that Aluminium Lidding Foil, provided by us, is made with soft and fully annealed Aluminium alloy AA-8011 that conforms to Aluminium Association specification.