-

+91 7383115721

Both metallised PET and BOPP have restored foil laminates for products such as snack foods, coffee and candy, which do not necessitate the finer barrier of aluminium foil. Metallised nylon and polyethylene are exercised in the meat export market. The controlled permeation extends shelf life. Metallised films are exploited as a subsector for cooking in microwave ovens. An example is a microwave popcorn bag. Many food items are also packaged using metallised films for outer shell only, as these create a put together with superior glitter when evaluated to competing products that use printed paper or polymer films.

Metallised PET films are exploited in NASA’s spacesuits to formulate them emission resistant and remain astronauts warm, and in proximity (aluminized) suits are used by AR-FF fire fighters for guard from the soaring sum of heat released from fuel fires. Silvered emergency blankets are also used to preserve a shock victim’s body heat. These reflective materials might also be used as part of industrial and commercial insulation (for example, insulated shipping containers.)

Insulating blankets made with Metallised PET were also employed as insulation in aircraft until security distress resulted in their deprecation.[5] In particular, it was found to be a major cause of the in-flight fire of Swissair Flight 111 on September 2, 1998.

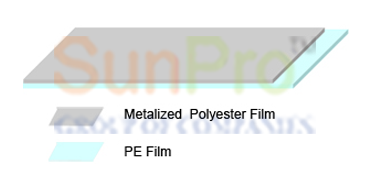

| PROPERTIES | UNIT | TYPICAL VALUE |

| Thickness | micron | 32 |

| Weight | grs/sqm | 37 |

| Yield | sqm/Kg | 27.03 |

| Density | gr/cm3 | 1.41 for MPET0.92 for PE |

| Emissivity | % | 0.3 ~ 0.4 |

| Reflectivity | % | 92 ~ 97 |

| Tensile Strength | Kg/cm2 | MD: 2000 |

| TD: 2100 | ||

| Elongation at Break | % | MD: 140 |

| TD: 130 | ||

| Lamination Temperature | 'C | 200 ~ 250 |

| Lamination Pressure | kg/cm2 | 8 |

| Remarks |

| -Core ID : 76mm (3inch) Standard -length : 5,000mtrs, Other lengths available On request -Thickness Tolerance : +/-7% Maximum -Wdiths : Up to 1520mm |

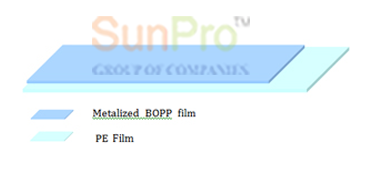

| PROPERTIES | UNIT | TYPICAL VALUE |

| Thickness | micron | 37 |

| Density | gr/cm3 | 1.41 for MBOPP & 0.92 for LDPE |

| Weight | grs/sqm | 37 |

| Yield | sqm/Kg | 27.78 |

| Reflectivity | % | 75~80 |

| Emissivity | % | 0.2 ~ 0.3 |

| Lamination Temperature | Temp | 200 ~ 250 |

| Lamination Pressure | kg/cm2 | 8 |

| Remarks |

| -Core ID : 76mm (3inch) Standard -length : 3,000mtrs-5,000mtrs, Other lengths available On request -Thickness Tolerance : +/-7% Maximum -Wdiths : 1520mm Max |