-

+91 7383115721

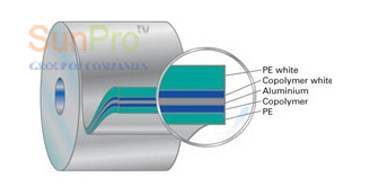

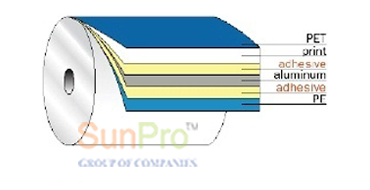

Flexible packaging is quickly rising as an efficient substitute to conventional metal, plastic and glass containers. It's light, simple to knob and money-spinning. And most imperative, it offers an superb exterior for printing. Multi layer foils can be offered different kinds of flexible packaging materials with amalgamations of diverse materials like Polyester film, Aluminium Foil, Paper, BOPP, LDPE, Cellophane etc without printing

Also can be offered in reverse printed film laminates. Multi Ply Laminates comprises of multi ply security laminates, multi ply semi rigid laminates etc.

This 3 ply is apt for packing conservative products like confectionery, tea, consumables etc. The final product specifications are made as per agreed contract with the customers based on the kind of products that are to be packed. Polyester to foil and foil to poly lamination is done by dry lamination.

| Structure | PET gsm +/-5% |

Foil gsm +/-8% |

LDPE gsm +/-5% |

| 12 mic PET/ 9 mic Foil / 37 mic LDPE | 16.8 | 24.3 | 34.5 |

| 12 mic PET/ 12 mic Foil / 37 mic LDPE | 16.8 | 32.4 | 34.5 |

| 12 mic PET/ 12 mic Foil / 50 mic LDPE | 16.8 | 32.4 | 46 |

| 12 mic PET/ 12 mic Foil / 62.5 mic LDPE | 16.8 | 32.4 | 57.5 |

| For all above structures: | |

| Aluminium Foil Alloy | AA 1200 / AA 1235 |

| Foil Finish | Matt / Bright |

| Bond Strength | 180 grams/ 15 mm (min) |

| Lamination Surface | Matt/ Bright |

| Printing Substrate | Polyester |

| Printing side | Top / Reverse printing |

| Text and Design | As per artwork |

| Repeat Length | As per artwork |

| Repeat Length Tolerance | +/- 0.5 mm |

| Registration | +/- 0.5 mm |

| Core Type | Plastic / Aluminium / Card Board |

| Core ID | 70 mm / 76 mm |

| Reel OD | 250-350 mm (standard) |

| OD Tolerance | +/-5 mm |

| Slit Width Tolerance | +/- 0.5 mm |

| Type of Joint | Single Butt/ Double Butt / Lap Joint |

| Type of Tape/ Colour | Cello Tape / Red Colour (standard) |

| Type of Packing | Wooden Case / Pallet / Corrugated Carton |

| Structure XX gsm Paper / XX micron LDPE/ XX micron Foil/ XX micron LDPE |

Paper gsm +/-5% |

LDPE gsm +/-5% |

Foil gsm +/-8% |

LDPE gsm +/-5% |

| 41 Paper/ 15 LDPE / 9 Foil / 25 LDPE | 41 | 13.8 | 24.3 | 23.00 |

| 41 Paper/ 17 LDPE / 9 Foil / 32 LDPE | 41 | 15.64 | 24.3 | 29.44 |

| 41 Paper/ 15 LDPE / 9 Foil / 37 LDPE | 41 | 15.64 | 24.3 | 34.04 |

| 41 Paper/ 20 LDPE / 9 Foil / 25 LDPE | 41 | 18.4 | 24.3 | 34.04 |

| For all above structures: | |

| Aluminium Foil Alloy | AA 1200 / AA 1235 |

| Foil Finish | Matt / Bright |

| Temper | Soft |

| Paper | Glassine / Other |

| Lamination surface | Matt / Bright |

| Sealing Strength | 600 grams/ 15 mm |

| Sealing Surface | LDPE to LDPE |

| Sealing temperature | 160 deg C |

| Dwell Time | 0.5 sec. |

| Printing substrate | Paper |

| Text, design, Shade | As per artwork |

| Repeat length tolerance | +/- 0.5 mm |

| Registration tolerance | +/- 0.5 mm |

| Core Type | Plastic / Aluminium / Cardboard |

| Core ID | 70 / 76 mm |

| Reel OD | 250-300 mm (standard) |

| Reel OD tolerance | +/- 5 mm |

| Type of Joint | Single butt / Double butt / Lap Joint |

| Type of Tape / Colour | Cello Tape / Paper Tape, Brown/Red/Black |

| Reel Width | As per artwork |

| Width tolerance | +/- 0.5 mm |

| Packing | Corrugated Cartons/ Pallets/ Wooden Cases |